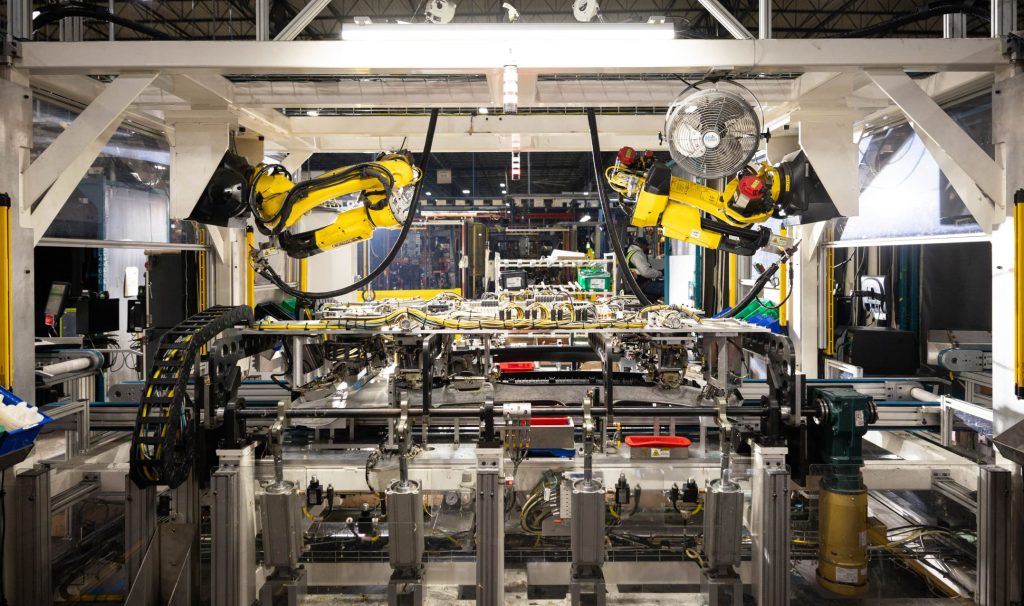

Precision. Control.

Continuous Improvement.

Control Methodology

Smart engineering for rapid and seamless innovation.

When an OEM launches or transitions a large-scale contract manufacturing warehouse operation, flawless execution is critical. Millions of parts are at stake, and any failure in process control can disrupt production, drive up costs, and create supply chain inefficiencies.

Our control methodology ensures seamless start-ups, built-in flexibility, and continuous performance optimization. From receipt to shipment, we engineer processes that anticipate potential risks and eliminate failure points before they occur.

By embedding rigorous process controls at every step, we ensure:

- Seamless, efficient start-ups that accelerate productivity from day one.

- Real-time flexibility to manage change without disruption.

- Ongoing process optimization and cost reduction through continuous improvement.

When precision, control, and continuous improvement are essential, CLI delivers.

The Three Pillars of our Control Methodology.

At CLI, quality isn’t an end goal – it’s a built-in advantage.

Engineered for Success

Our approach aligns with Plan for Every Part (PFEP) methodology and follows W. Edwards Deming’s quality principles, ensuring process stability and continuous improvement.

Commitment to World-Class Quality

From Master Dot methodology to our formal change management process, CLI’s systems exceed the highest industry standards.

Relentless Continuous Improvement

By applying Lean techniques and eliminating waste and process variability, we maximize efficiency and cost savings for our customers.

Advanced Quality Planning

Engineered to Prevent Errors.

Our Advanced Quality Planning approach integrates:

- Potential Failure Mode and Effects Analysis (PFMEA)

Identifying risks and engineering solutions before issues arise. - Process-Specific Work Instructions

Standardizing best practices for efficiency and accuracy. - Irreversible Corrective Actions

Implementing error-proofing methodologies that permanently eliminate root causes of failure.

By embedding quality at every step, we provide a highly controlled environment that prevents costly disruptions and ensures on-time, flawless execution.

Give us your toughest challenge.

What variables have you struggled to control in your process? Our expert problem solvers are ready to listen. Reach out to CLI today.

Contact Us